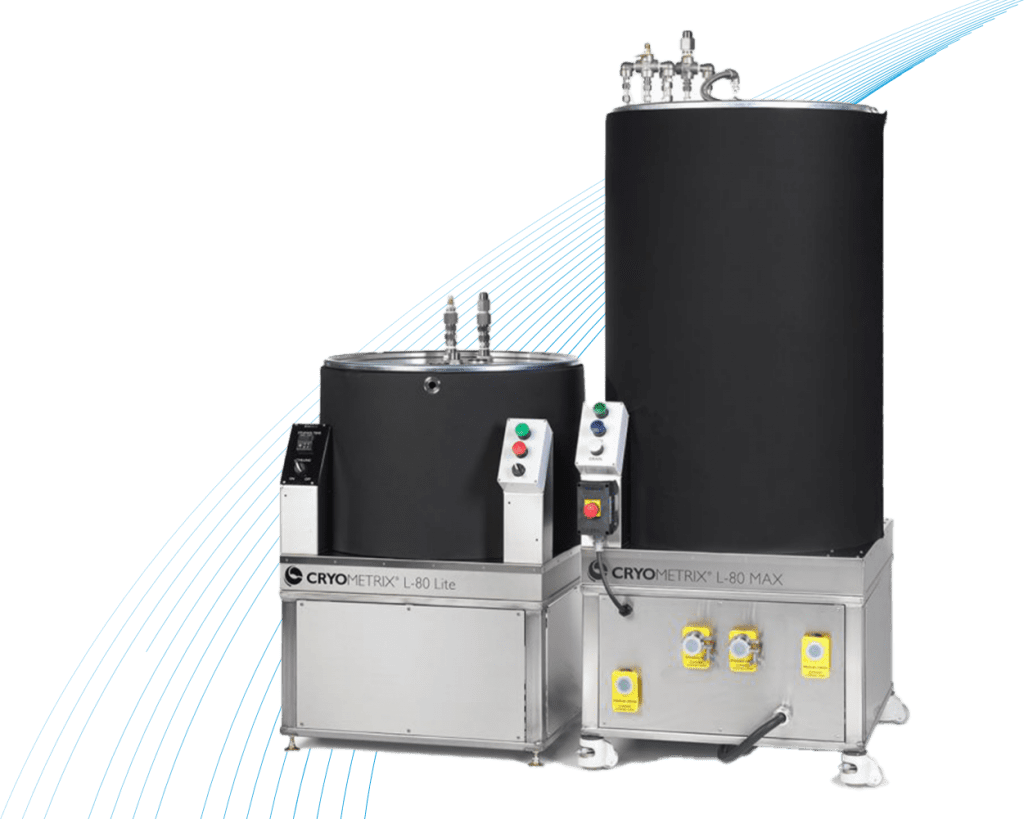

Cryometrix L-80 Max Chiller

Ultra-Fast, Energy-Efficient, and Scalable Liquid Nitrogen Chiller for Ethanol Extraction and Winterization

The Cryometrix L-80 Max Ethanol Chiller represents the next generation of liquid chilling technology. Built with patented liquid nitrogen (LN2) cooling systems, the L-80 delivers unmatched speed, reliability, and cost efficiency for ethanol chilling. Whether your facility is focused on CBD oil extraction, cannabinoid winterization, research, or industrial-scale production, the Cryometrix L-80 offers the fastest ethanol chill times in the industry without the high energy demands or frequent maintenance of mechanical chillers.

Where traditional chillers rely on complex compressors, refrigerants, and HVAC support, the Cryometrix L-80 eliminates these inefficiencies. Instead, it leverages the ultra-low boiling point of LN2 (-196°C) to quickly cool ethanol to extraction-ready temperatures, down to -80°C within 50 minutes for 120 gallons. This technology not only improves extraction purity but also lowers operating costs, reduces downtime, and provides a more scalable solution for growing facilities.

Industry-Leading Performance

The Cryometrix L-80 is designed to maximize chilling performance while minimizing operator effort. At the push of a button, the L-80 automates filling, chilling, and draining cycles, giving technicians precise and reliable ethanol cooling for every batch.

- 30 gallons to -40°C in <10 minutes

- 120 gallons to -40°C in 25 minutes

- 120 gallons to -65°C in 45 minutes

- 120 gallons to -80°C in 50–55 minutes

Compared to compressor-based chillers, which struggle to reach these ultra-low temperatures consistently, the L-80 provides uniform cooling (±1°C) across every gallon. This ensures high- quality extraction results, improved efficiency, and reduced post-processing time.

Lower Energy Costs and Sustainability

One of the most significant advantages of Cryometrix LN2 technology is its ability to operate with 95% less energy consumption than conventional chillers. Because the L-80 does not rely on compressors or refrigerants, it produces no heat exhaust, eliminating the need for costly HVAC systems to cool your workspace.

This not only reduces your utility bills but also creates a more eco-friendly, sustainable solution. Cryometrix systems emit only nitrogen gas into the atmosphere, a harmless byproduct since nitrogen already makes up more than 75% of the air we breathe. No refrigerants, oils, or CFCs are used, ensuring compliance with environmental regulations and reducing long-term operational risk.

Compact and Scalable Design

The Cryometrix L-80 combines maximum power with minimal footprint. At just 33” x 33”, the unit takes up less than 16 square feet of floor space, making it ideal for labs, extraction facilities, and manufacturing environments with limited room. Unlike bulky traditional systems, the L-80 can be placed side by side or back to back, allowing facilities to easily expand capacity as demand grows.

This modular approach means you can start with a single unit and scale up to multiple systems without requiring significant electrical, HVAC, or infrastructure upgrades. For facilities planning long-term growth, the L-80 provides true scalability with minimal capital investment.

Applications Across Industries

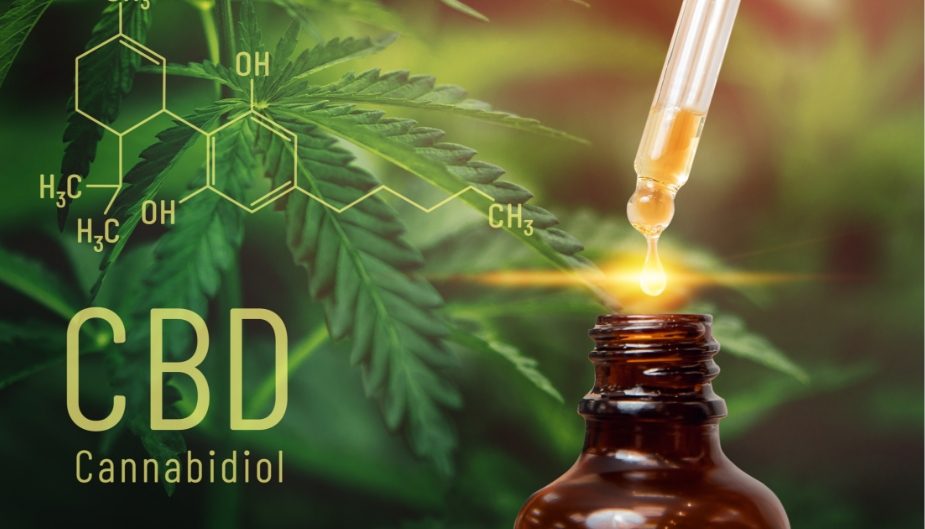

CBD Extraction

Ethanol extraction is one of the most common methods used in CBD and cannabinoid processing. However, the warmer the ethanol, the more unwanted plant waxes, fats, and chlorophyll are extracted along with cannabinoids. By chilling ethanol down to sub-zero temperatures, the Cryometrix L-80 ensures higher cannabinoid purity, reducing unwanted compounds and improving extraction yield.

CBD Oil Winterization

After initial extraction, oils often contain impurities such as waxes and fats. Winterization requires chilling ethanol-extract mixtures so these particulates solidify and can be removed. The L-80 accelerates this step, producing cleaner, higher-quality CBD oil with less manual processing.

Research and Development

For labs conducting small-batch tests or experimental extraction runs, traditional chillers can be prohibitively expensive and oversized. The Cryometrix L-80 provides a cost-effective, compact, and powerful alternative, enabling researchers to access ultra-cold ethanol chilling without overspending.

Manufacturing and Industrial Production

The L-80 is not just for small operations. Its automated fill levels, rapid chill cycles, and durable stainless-steel design make it equally suited for large-scale industrial extraction and manufacturing facilities that demand consistency, scalability, and long-term reliability.

Features and Benefits

Cryometrix Liquid Nitrogen Technology

- Uses no compressors, oils, or refrigerants

- Runs silently with minimal maintenance needs

- Capable of chilling to -80°C quickly and efficiently

- Reliable performance regardless of outside temperature or humidity

User-Friendly Operation

- 7” touchscreen LCD with intuitive interface

- One-button automated fill, chill, and drain functions

- Built-in data logging for up to 30 users

- Security features with configurable access levels

Durable and Sanitary Design

- Constructed with 304 stainless steel

- Easy-to-clean surfaces and sanitary Triclamp connections

- Closed nitrogen system ensures ethanol never contacts LN2 directly

Safety and Compliance

- Peer-reviewed for C1D2 environments

- CE marked for global use

- Completely sealed nitrogen system ensures operator and product safety

Speed and Efficiency

- Fastest ethanol chill times in the industry

- Fill and drain 120 gallons in as little as 4 minutes

- Temperature uniformity within ±1°C

Technical Specifications

| Capacity | 120 gallons (30 and 60-gallon automated fill options) |

| Temperature Range | +20°C to -80°C |

| Performance | 120 gallons to -40°C in 25 minutes 120 gallons to -80°C in 50–55 minutes |

| LN2 Consumption | 1–2 gal/min (3.78–7.5 L/min) |

| Electrical Requirements (US) | 120 VAC, 12A, NEMA 5-20 Plug |

| Dimensions | 33”Wx38”Dx85”H |

| Certifications | C1D2 Peer Reviewed, CE Certified |

| Manufacture | Made in the U.S.A. |

Why Cryometrix?

Cryometrix has been pioneering LN2-based freezing and chilling solutions for years, bringing next-generation technology to industries that demand speed, reliability, and precision. By avoiding mechanical compressors and refrigerants, Cryometrix systems:

- Last up to 4 times longer than comparable chillers

- Require far less maintenance and fewer replacement parts

- Provide consistent performance regardless of environmental conditions

- Use 7x less electricity than traditional systems

- Eliminate the need for expensive HVAC modifications

Whether you are operating a small-scale lab or a large production facility, Cryometrix delivers a cost-efficient, environmentally friendly, and future-proof ethanol chilling solution.

Customer-Focused Engineering

The Cryometrix L-80 was designed with the customer in mind. Extraction technicians benefit from a system that is simple to use, requires little training, and delivers repeatable, high-quality results. Operations teams gain from reduced overhead, lower energy bills, and a compact design that optimizes facility space. End users ultimately benefit from the improved purity and consistency of extracted cannabinoids.

L-80 MAX

Features

(configure control to setpoint, access, and other advanced security settings)

Performance

C1D2 Skid

(Width x Depth x Height)

(33 inches x 38 inches x 85 inches)

(Diameter x Height)

(30 inches x 46 inches)

Liquid Nitrogen Enclosure

Electrical Control Panel (United States)

Electrical Control Panel (Europe)

Certifications